Hot news

Contact information

- Phone:86-714-6393188

- TelePhone:86-714-6393188

- Q Q:297705516

- Email:hongda@m.tow-motorcycle.com

- Address:Machinery Industrial Park, Huangjinshan Development Zone, Huangshi City, Hubei Province

Pubdate:2020-09-28 11:12 Click:

brand:Yike

model:

Processing customization:

Mold material:

Mold usage:

Mold origin:

Process type:

model:

Processing customization:

Mold material:

Mold usage:

Mold origin:

Process type:

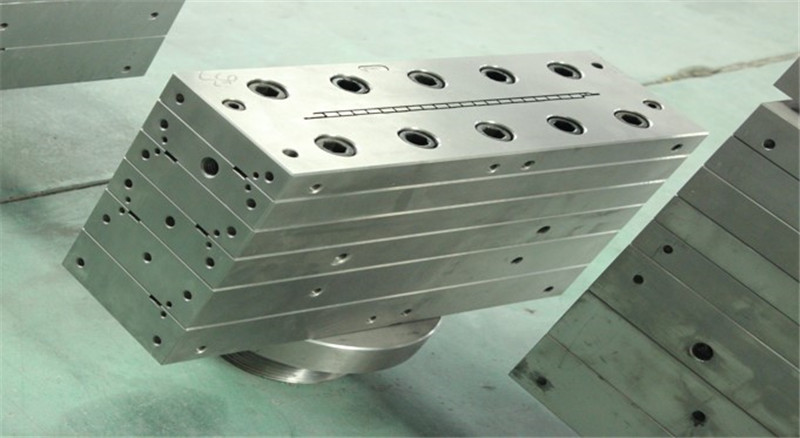

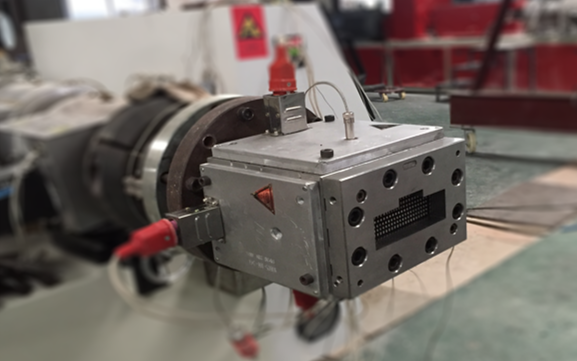

Profile mould

With more than 20 years of design and manufacturing experience, advanced design, excellent production and optimal price, it is the first professional manufacturer engaged in the design and production of door and window profile dies in China. It carries out personalized customization and design, so as to give full play to the extruder capacity and achieve the best physical properties of the products.

Application range:

The first mock exam is PVC plastic steel doors and windows, flat doors and windows, sliding doors and windows, guardrails, wire slot pipes, PVC pipes, a multi cavity tube, foam tube, winding pipe and so on.

Extrusion material:

UPVC, PVC soft hard coextrusion, PVC multicolor co extrusion, multi material co extrusion, full package co extrusion, embossing co extrusion, etc

Technical advantages:

1. Automatic CNC machine tool has high machining precision and minimal mould error

2. According to the customer's raw materials, the design experience value is unique to each company

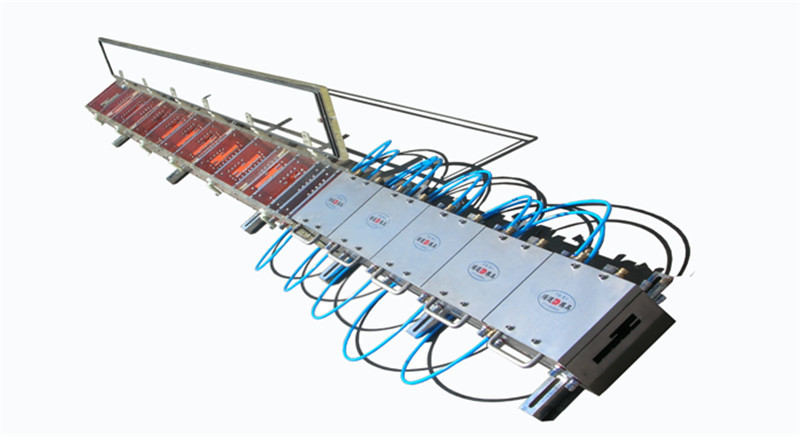

3. Reasonable die cavity parameters and water gas arrangement can give full play to the best production capacity of the extruder

4. Adapt to the production of various formulations and different equipment

5. Accurate reset ensures the continuous production capacity of the mould

Main types of mould:

Single cavity mold: high extrusion speed, main profile extrusion speed is more than 2.5 meters per minute

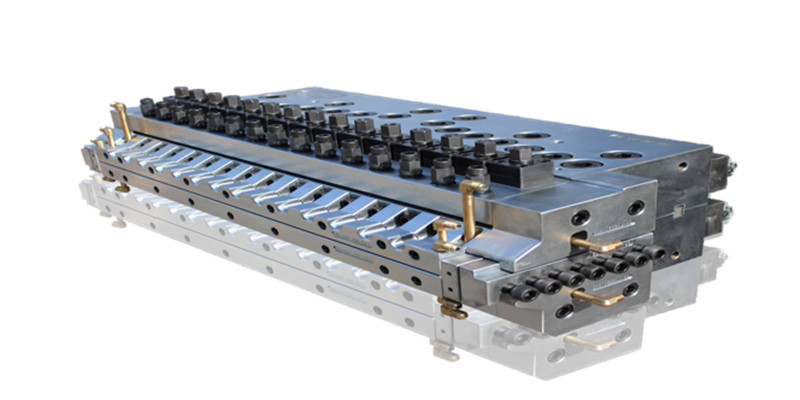

Double cavity mold: give full play to the maximum capacity of extruder, stable and efficient production

Multi cavity mold: used in small section products, improve production capacity

Special mold: the size and extrusion amount are super conventional, and customized according to customer requirements

Coextrusion mold: coextrusion soft rubber strip or coextrusion color surface, coextrusion layer is uniform

Full cladding mold: new material for outer layer and old material for inner core, which can save material cost and avoid steel lining.

pre:none

|

next:Sheet die